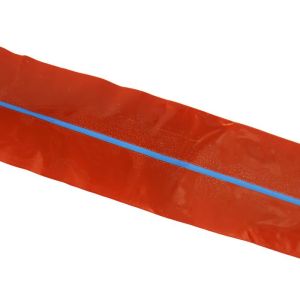

Braided Sleeving

All Braided Cable Sleeving Made In USA

BuyHeatShrink.com is equipped to meet all your wire management requirements with American-made braided sleeving. Our team boasts extensive expertise in braiding, as well as in the design and production of wire harnesses and monofilaments. We offer a wide selection of solutions, including Electrical Insulation through coated braided fiberglass, and Abrasion Resistance with our bold PET Colored Braided Sleeving, FR Braided Sleeving for flame resistance, alongside Nylon, Nomex®, Kevlar®, Halar®, and cotton variants. For Thermal Protection, our lineup includes metalized products, T-Glass, Ceramic, Quartz, and Silica braided sleeving. We also provide EMI/RFI shielding options like tin-coated and silver-coated copper braids - QQB575. For those in need of extreme Chemical Resistance, we carry Ryton PPS, Teflon PFA, and Halar E-CTFE. Whether it's the versatility of Techflex Braided Cable Sleeving you seek or specialized protection, we have the capability to supply it all.