The store will not work correctly when cookies are disabled.

JavaScript seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Javascript in your browser.

Bentley Harris

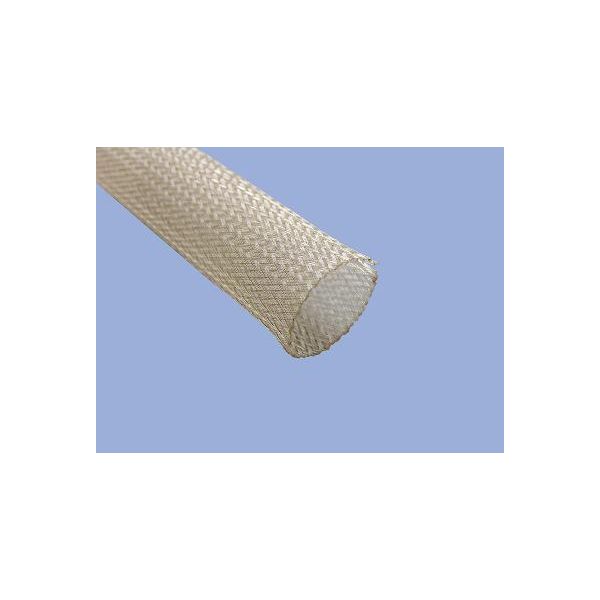

Bentley Harris Expando 686DM Ryton/PEEK Braided Sleeving

Expando 686DM Ryton/PEEK Braided Sleeving NOTE - THERE IS AN 8 WEEK LEAD TIME

Features:

Excellent cut through and abrasion resistance

Continuous use temperature of -70°C to 200°C (-103°F to 392°F)

Patented Dual monofilament construction for a exceptional abrasion resistance in a wide variety of applications.

Constructed from 0.008" PPS and 0.011" PEEK monofilaments.

Melt temperature of PPS is 285°C (545°F) and melt temp of PEEK is 334C (633°F)

Expands up to three times its resting diameter

Halogen Free, ROHS compliant

Self Extinguising

Resists Gasoline, Jet Fuel, Hydraulic Fluid, lube oil, de-ice fluid, salt water, Engine Chemicals & Cleaning Solvents

UL VW-1 and FAR Part 25 flame rated

Low smoke generation and low outgassing

Sold in Black and Natural (Tan).

Diameter

Part Number Expansion min Expansion Max

Buy

1/8"

BSBH-686DM-1-8 3/32" 1/4"

1/4"

BSBH-686DM-1-4 1/8" 3/8"

3/8"

BSBH-686DM-3-8 3/16" 5/8"

1/2"

BSBH-686DM-1-2 1/4" 3/4"

3/4"

BSBH-686DM-3-4 1/2" 1 1/4"

1-1/4"

BSBH-686DM-1-1-4 3/4" 1 3/4"

1-3/4"

BSBH-686DM-1-3-4 1" 2 3/4"

2"

BSBH-686DM-2 1 1/4" 3"

2-1/2"

BSBH-686DM-2-1-2 1 1/2" 4 1/2"

Expando 686DM

BSBH-686DM-1-1-4

1 1/4" Bentley Harris Expando 686DM Ryton/PEEK Braided Sleeving

BSBH-686DM-1-2

1/2" Bentley Harris Expando 686DM Ryton/PEEK Braided Sleeving

BSBH-686DM-1-3-4

1 3/4" Bentley Harris Expando 686DM Ryton/PEEK Braided Sleeving

BSBH-686DM-1-4

1/4" Bentley Harris Expando 686DM Ryton/PEEK Braided Sleeving

BSBH-686DM-1-8

1/8" Bentley Harris Expando 686DM Ryton/PEEK Braided Sleeving

BSBH-686DM-2

2" Bentley Harris Expando 686DM Ryton/PEEK Braided Sleeving

BSBH-686DM-2-1-2

2 1/2" Bentley Harris Expando 686DM Ryton/PEEK Braided Sleeving

BSBH-686DM-3-4

3/4" Bentley Harris Expando 686DM Ryton/PEEK Braided Sleeving

BSBH-686DM-3-8

3/8" Bentley Harris Expando 686DM Ryton/PEEK Braided Sleeving