The Truth About Water Resistant Vs. Waterproof Wires

The Truth About Water Resistant Vs. Waterproof Wires

Water is chaos. It is fluid power that doesn’t follow rules, ignores boundaries, respects no path, and asks no permission.

Your wires, on the other hand, are power in contract. Currents are contained, controlled, follow order, and flow only where they belong.

And never the two shall meet.

Where Water Strikes First

When water meets wire, everything changes.

Water isn’t just powerful, it’s sneaky. It doesn’t need to be visible to be destructive. A single drop, a hairline fracture, a humid morning. That’s enough to start unraveling your electrical setup from the inside out.

Here are some of the most common vulnerabilities for water ingress around wires:

- Ends, Connections, & Splices: Wherever wires join, start, or stop, the protective jacket does, too. These are natural, necessary junctions, but they’re water welcome mats. Once inside, moisture wicks its way along the bare metal and spreads far beyond the original breach.

- Junction Boxes, Breaker Panels, & Conduit Entries: Wires gather, split, or change direction in these hubs. They’re full of seams and openings, and many are outside. All it takes is one angle, gap, flaw, or low spot for water to make itself at home.

- Damaged or Compromised Insulation: Insulation is your wire’s only line of defense, but it’s more vulnerable than you think. UV exposure causes microcracks. Rodents bite. Stray staples puncture. Tight bends, friction, age, impact, sunlight. They all weaken in practically invisible ways.

- Stranded Wire: The mechanical spaces hiding between each wire in a twisted strand are the perfect place for moisture to gather, travel, and cling.

- Vertical Wire Runs: If there’s moisture present in a vertical or steeply angled run, gravity jumps in for the assist. Water slips and slides down the entire wire length and ends up pooling at the lowest point.

Water and metal don’t play nice. So when water gets in at one of these vulnerabilities, it wreaks havoc.

When Water Attacks Your Wires

Water destroys simply by being liquid. The oxygen, ions, and impurities that it carries accelerate the damage. Corrosion starts within minutes of contact, eating your wires from the inside out. And once it starts, there’s no stopping it.

Visible corrosion takes days or weeks to appear. If rust forms under the wire jacket, behind breaker terminals, or inside a junction box–you may never see it. The more moisture there is, the faster corrosion spreads, hungry for more metal.

Corrosion builds along the wire, making it work overtime to pass current. Resistance grows. Conductivity decreases. Energy is lost. Bills climb. The harder it works, the hotter it gets.

Overworked, overheated wires can melt insulation, interrupt power, trip breakers, short, shock, or spark. Left unchecked, water damage will take down entire circuit panels, cause total system failure, or worse–take lives.

Water is unapologetic about its actions, but its consequences are preventable.

Water Resistant vs. Waterproof: What’s the Deal?

Understanding the difference between water resistant and waterproof doesn’t just protect your wires–it protects your property, your time, your energy, and sometimes even your life.

Water-Resistant

This is the mostly, usually, and sometimes.

“Water resistant” means a product is anti-water, but only to a certain point. It’s there to slow down moisture–not stop it altogether. It repels and protects for a little while and against a little water. It tries, but given enough time, pressure, or presence…the water is always going to win. Think raincoats and umbrellas–you’ll be dry in a drizzle, not a deluge.

Waterproof

This is the fully, always, and completely.

“Waterproof” means a product is so anti-water and battle-ready that it’s impenetrable. It seals, and it is certain. It doesn’t leak, and it doesn’t let up. Come pressure, prolonged exposure, and deep or high water, there’s no question. Waterproof wins against water–every time. Think wetsuits and full scuba gear–the water stops here.

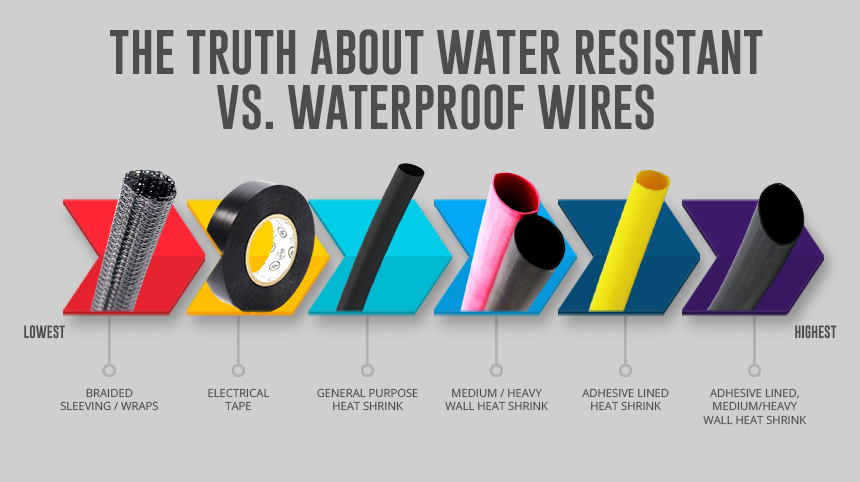

Which Products Actually Work Against Water?

Any product that works to keep wires dry is an anti-water warrior–on your side, fighting the good fight. They just don’t all fight at the same level. So let’s look at what’s out there defending your wires against water from surface-level resistance to full-on electrical waterproofing.

Spoiler: If it doesn’t have an adhesive lining, it’s not waterproof, period.

Braided Sleeving

Defense Level: Minimal Water-Resistance

Best For: Dry installs, bundling, structural support, and airflow

Braided sleeves give lightweight support designed to breathe, not block. Their tight, open weave protects against friction and impact, but not water. Their materials wick moisture and minor spills or splashes away from heat-sensitive cables, but they won’t stop water from creeping in.

Electrical Tape

Defense Level: Basic Water-Resistance

Best For: Quick wraps, temporary sealing, and indoor moisture control

Electrical tape offers water resistance as a courtesy, not a commitment. Its pressure-sensitive backing seals for the short term, but that barrier breaks down quickly. It’s a helpful delay for slowing moisture, but it won’t stop water or the elements.

General Purpose Heat Shrink Tubing

Defense Level: Moderate Water-Resistance

Best For: Insulating wires, repairs, reinforcements, and everyday protection

Wall Upgrades Available: Medium - Heavy for extra thickness in tougher environments and more durable moisture prevention.

General purpose heat shrink tubing wraps around wires for a snug, 360-degree barrier of moisture resistance. Its outer wall deflects humidity and incidental moisture. It’s a reliable shield and your best defense before full waterproofing. If you’re looking for stronger or caustic liquid-resistance, without an adhesive lining, try a specialty material like Viton, known for its high temperature and chemical resistant properties.

Adhesive Lined Heat Shrink Tubing

Defense Level: WATERPROOF

Best For: Outdoor installs, buried splices, submerged conduits, weather-ready wires, boat/marine use, and high moisture environments

Wall Upgrade Available: Medium - Heavy for enhanced thickness, extreme protection, and the absolute BEST wire waterproofing on the market.

Waterproofing starts here–at the adhesive lining. It is the secret weapon for waterproof wires.

Not all heat shrink has it. But any tubing that comes with a layer of hot melt adhesive pre-applied to its interior wall is called dual wall–and that adhesive lining is the only way to achieve 100% watertight seals and permanently waterproof wires.

When heat is applied, the inner adhesive wall melts and flows. It fills gaps and cracks. It pushes air out. It cures to cool in minutes. It hardens and bonds directly to every surface. This is flexible, waterproof armor, and now it’s welded shut.

Adhesive lined heat shrink is a full stop. Impenetrable. It isn’t just protection–it’s prevention. And it's failproof. These seals start dry, stay dry, and they last underground, under pressure, and underwater–indefinitely.

If you want it waterproof, you need an adhesive lined warrior.

Adhesive Lined Butt Splice Connectors and Electric Terminals

Defense Level: WATERPROOF

Best For: Wire splices, repairs, and terminations in wet, buried, marine, or outdoor environments

Types Available: Butt, ring, hook, spade, block spade, step down, 3-way, and 4-way (all options available in multiple wire gauges)

Adhesive lined connectors and terminals bring waterproofing straight to the connection point.

These crimp-and-shrink components combine premium metal barrels for conductivity with a hot melt adhesive lining. The result? Fast, permanent, and always waterproof wire splices–sealed from the inside out.

Waterproof wire connectors never disconnect. They never rust. They are built to block out rain, flood, submersion, and condensation to keep connections safe, dry, and sealed tight–no matter what or where there’s no water here.

How To Keep Wires Dry: Layered Defense

Water is hostile. It strikes without warning and attacks from all sides. Your wires are going to need a strong defensive strategy to withstand the liquid onslaught. What they need is layers.

Use water-resistant and waterproof products together to build layers at the wettest and weakest points. Your goals are simple: replace, repair, and most importantly, reinforce.

Since end points, splices, and connections are the most prone to water ingress, this is a great place to start. Cover weak, water-prone wire ends with a layer of heat shrink to reinforce water resistance. Or use dual wall heat shrink on top of old connections to waterproof them.

If possible, swap out preexisting splices with dual wall, waterproof wire connectors and terminals. Finish them with a piece of dual wall heat shrink for four layers of forever-dry wire protection. Can’t disconnect? Get all the benefits of adhesive lined heat shrink in tape form and go waterproof crazy!

But you might not need that much.

- Outdoor electrical wiring needs at least two layers of protection at all times. For partially enclosed outdoor spaces (like junction boxes, sheds, or roof overhangs), one stronger layer might be enough. But in damp, humid climates get an adhesive lining involved.

- Interior wiring can be protected with general purpose tubing alone. (It’s not going to pour indoors, so you don’t need to overbuild.)

- Braided sleeving also works well for indoor and home electrical wiring protection. Team up with electrical tape (or general purpose tubing) to reinforce and seal moisture-sensitive ends for a clean, dry finish.

- And in a pinch, electrical tape alone can delay moisture entry on any wire until you can come back with a sturdier layer.

Repair visibly damaged cable jackets with a layer of heat shrink to restore electrical integrity and add a buffer of moisture resistance. But if your wire insulation is worn, aged, or cracked and exposed to the elements, make sure you double up reinforcements with waterproof, dual wall heat shrink.

Water is unrelenting. And it’s out to get your wires. The more water there is, the more layers you’ll need. Keeping your wires dry takes strategy, attentiveness, and layered defense.

Watertight Wisdom

Every good defensive strategy is backed by good wisdom. So, here are some watertight truths and insights to help you ultimately win the battle of water vs. wire.

- Water-resistant products aren’t weak. They’re just built for a different fight–practical protection where there’s no direct or constant water exposure.

- When in doubt, upgrade to the adhesive lining. Waterproof solutions eliminate risk, worry, wasted money, and time–because they always stay connected, dry, and safe. You’ll never regret going waterproof.

- Water doesn’t just mean storms and floods. Air, gravity, heat, steam, humidity, thermal cycling–it’s all part of Team Moisture, and it all causes damage–even if you can’t see it.

- Thicker walls resist pressure–not moisture. They’re better for burial or submersion, but thickness alone doesn’t make heat shrink more waterproof.

- Adhesive linings = waterproof. That means dual wall tubing, connectors, and terminals are the only way to bond, seal, and permanently lock out moisture.

Water takes no prisoners. It drowns them.

It is sneaky, aggressive, and unpredictable. It attacks without mercy, and unprepared wires won’t survive. Water is the enemy.

Defend your wires and connections before it’s too late. Build layers of water-resistant and waterproof armor for them now. So that when water does strike, your wiring is ready to stand its ground. Hold its own. Fight the good fight. And emerge from the battle–dry and victorious.

Don’t just cover your wires–armor them. We’ve got the gear at BuyHeatShrink.com.